Boost Manufacturing Efficiency with D365 Finance Production Floor Execution

Imagine a manufacturing facility where every employee has instant access to tools, real-time data, with work instructions. This is the reality enabled by D365 Finance Production Floor Execution (PFE). As a centralized hub, PFE replaces outdated paper workflows with a streamlined system accessible on tablets, workstations, or mobile devices. For operations leaders, it’s more than software, it’s a tool for streamlined workflows, decisions, and faster.

Why Choose PFE? Key Benefits for Manufacturing Leaders

Real-Time Visibility and Decision-Making

For process owners, PFE provides live production dashboards that eliminate blind spots, allowing you to track progress, material consumption, and bottlenecks in real time. Address issues as they arise rather than waiting for end-of-day reports.

For Teams, workers can update job statuses and report scrap or downtime in seconds, enhancing data accuracy and freeing them from labor-intensive manual logs.

Reduced Errors and Streamlined Processes

Process Owners can automate tasks like time tracking, material usage recording, and compliance monitoring. Reduce human error by up to 50% while ensuring operational traceability through features like barcode scanning.

Example: By scanning raw material batches, you can link them directly to specific production orders, minimizing allocation errors and strengthening audit compliance.

Boosted Efficiency and Throughput

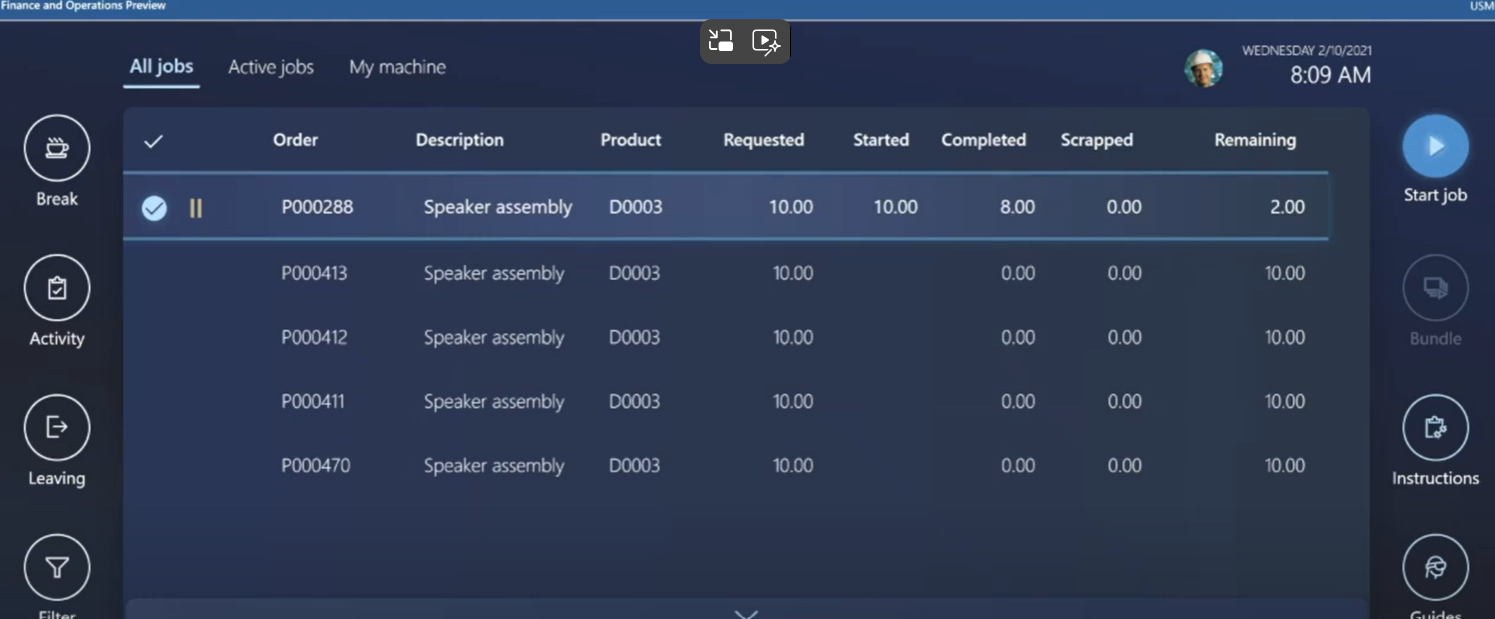

Process owners can tailor role-based interfaces for each job type. For instance, an operator’s view may include quick-start actions like “Start Job” or “Report Scrap.” This role-specific optimization reduces task-switching time by 40%.

Example: Workstations for assembly tasks can show only ongoing jobs and quality checkpoints to speed up workflows without compromising on accuracy.

Smarter Analytics for Optimized Performance

PFE integrates seamlessly with tools like Power BI to provide actionable insights into metrics such as Overall Equipment Effectiveness (OEE), labor productivity, and material variance. Make data-informed decisions to refine schedules and support continuous improvement initiatives.

Example: By tracking machine downtime causes hourly, you’ll be able to recalibrate maintenance schedules and significantly improve equipment uptime.

Better Quality Control and Traceability

With quality control and stronger traceability, process owners can record defects or deviations immediately and trigger automated quality workflows to resolve potential issues promptly. With just a few clicks, trace entire production batches from raw material to finished product.

Example: If a defective raw material batch is flagged, PFE pinpoints all affected outputs and halts shipments instantly to prevent further escalations.

PFE in Action: Transformative Scenarios

Job Management: Enable workers to view assigned tasks, start or stop operations, and report completed quantities with a single tap, all within a unified interface.

Time and Attendance: Simplify time tracking by allowing employees to clock in, log breaks, and record indirect activities, such as training, directly from the shop floor.

Material Management: Leverage scanning capabilities to instantly deduct materials from inventory and attach relevant batch or serial numbers to production orders.

Real-Time Quality Reporting: Identify and report defects mid-process to trigger alerts for quality control (QC) teams, allowing them to intervene quickly before issues worsen.

Digital Work Instructions: Embed standard operating procedures (SOPs), diagrams, or safety guidelines within the PFE interface to ensure every task is executed correctly.

Collaborative Tools: Assign jobs to teams and monitor collective performance without requiring redundant individual updates.

Strategic Deployment Areas for PFE

|

Area |

PFE Use Case |

|

Production Lines |

Real-time task and job status monitoring for assembly or processing lines. |

|

Workstations |

Customized, task-specific views for manual or semi-automated workstations. |

|

Quality Control |

Logging inspection details with options for photo or document attachments. |

The Competitive Advantage of PFE

Production Floor Execution offers unparalleled control, visibility, and strategic agility for manufacturers aiming to drive operational excellence. By automating labor-intensive tasks, empowering employees with intuitive digital tools, and leveraging real-time data for decisions, your organization is not just meeting today’s demands but also will be positioning itself for long-term success. It’s a shift toward data-enabled decision-making, lean manufacturing, and sustainable growth strategies. With PFE, you’re enabling continuous improvement that impacts both the workforce and the bottom line.