Increasing Supply Chain Resilience with Dynamics 365 Supply Chain Management

Traditionally, supply chain strategies have focused on cutting costs and improving productivity. This has led to numerous organizations depending on a single, often offshore, supplier for key subcomponents to save on labor costs. Yet, this strategy is fragile, presenting a single point of failure that could disrupt the entire supply chain. Conversely, simply increasing the number of suppliers does not automatically translate to a more resilient supply chain; it requires robust relationships and clear communication channels with these suppliers. The most effective strategy is to spread the procurement of essential parts across multiple suppliers, known as multi-sourcing.

However, adopting a multi-sourcing approach is not without its complications. In this blog, we aim to unpack the intricacies of multi-sourcing and show how leveraging the newly introduced multi-sourcing feature within Microsoft Dynamics 365 Supply Chain Management can aid in mitigating these issues.

Specify multisource policies for supply resilience

When it comes to multi-sourcing, the principal challenges include deciding the method to divide the supply of an item among various suppliers and determining which supplier to assign to a specific purchase order. The multi-sourcing capabilities in Supply Chain Management simplify these processes.

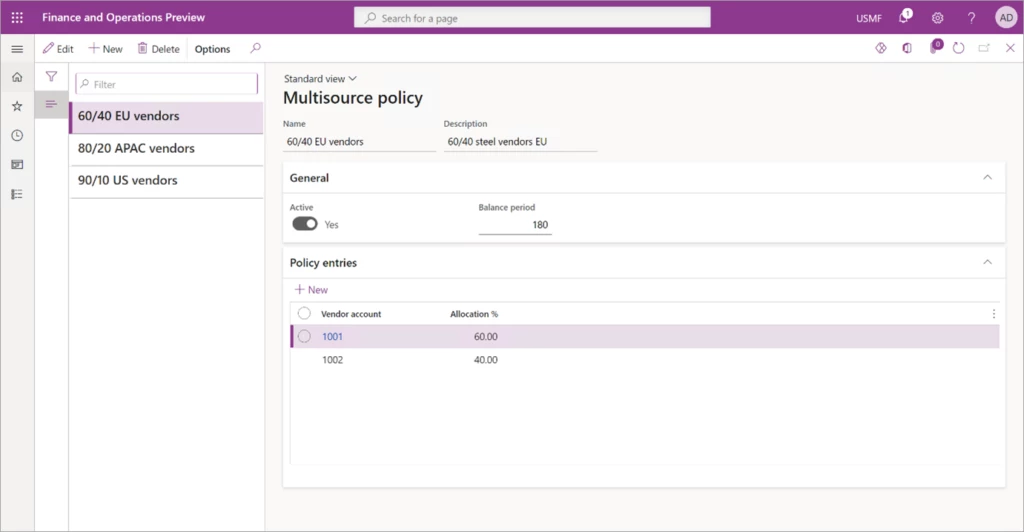

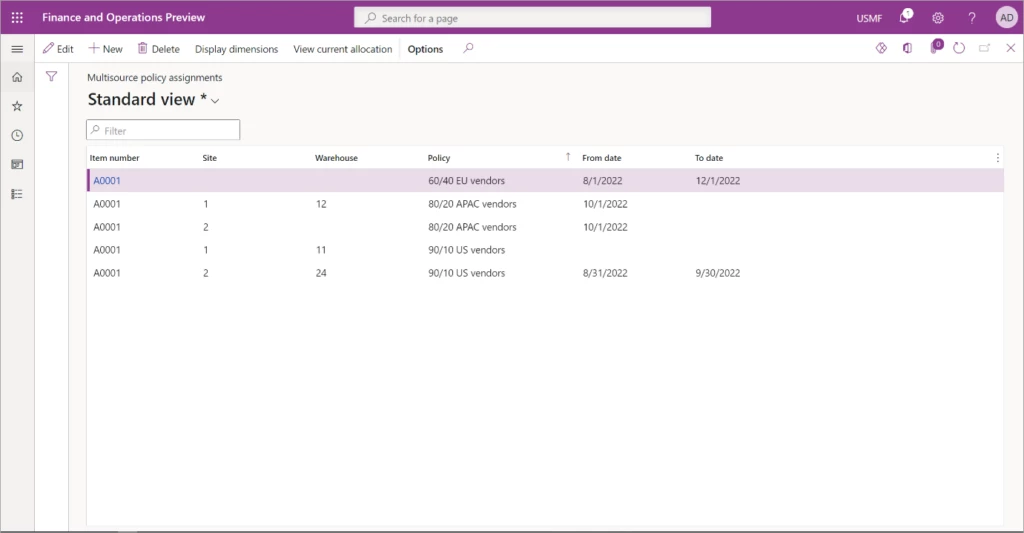

Now, it’s possible to define a multisource policy that not only identifies your preferred vendors but also allocates specific percentage targets for their supply contribution. For instance, you may decide that your primary vendor will provide 80% of your supply needs, while a secondary source might supply the remaining 20%. Alternatively, you could choose to allocate your orders equally among three different vendors.

You can also specify the period in which the policy applies. Then just assign the policy to a product or set of products.

When the Planning Optimization function generates a planned order, it selects vendors in such a way that your established targeted percentages are achieved progressively. This means that while a single vendor may be allocated the entire supply initially, subsequent orders will be distributed among different vendors to maintain the balance as per the group strategy.

Moreover, certain vendors may have minimum order requirements. The multi-sourcing feature in Supply Chain Management accommodates this by allowing you to specify minimum order quantities for each supplier, which are then honored by the Planning Optimization.

Additionally, you have the capability to compare the actual percentages fulfilled against the percentages outlined in your multisource policy. This comparison acts as a tool to track and ensure the robustness of your supply chain.

Choose the products you should multisource first

The new supply risk assessment workspace makes it simpler to find products that are planned to be purchased from one supplier. These may be good candidates for multi-sourcing to start increasing your supply resiliency.

The following recommendations can help you achieve higher supply resiliency:

- Multisource products: Distribute the procurement of parts across multiple vendors, beginning with the most essential components if you’re new to this approach.

- Diversify your supply in geography and size: Balance your sourcing strategy with a mix of local suppliers for quick turnaround and offshore suppliers that may offer cost benefits but come with longer lead times.

- Maintain good supplier relationships: Ensure you maintain excellent communication and business rapport with your suppliers. This collaborative stance enhances your ability to manage and adjust to supply chain disruptions swiftly, meeting customer demands more effectively.

- Build long-term partnerships: Aim for enduring and trust-based partnerships with suppliers. This long-term perspective is key for weathering disruptions and is preferable to a high rate of supplier turnover.

- Assess your supply risk: Evaluate the performance of your suppliers using metrics such as purchase order deliveries as requested, on-time in-full deliveries, on-time deliveries, and in-full deliveries. Dynamics 365 Supply Chain Management makes this easier using the new supply risk assessment workspace.

Next Steps

If you are interested in learning more about multi-sourcing in Microsoft Dynamics 365 for Supply Chain Management, contact us here to find out how we can help you grow your business. You can also email us at info@loganconsulting.com or call (312) 345-8817.