The Importance of Inventory Dimension Control in D365 F/SCM

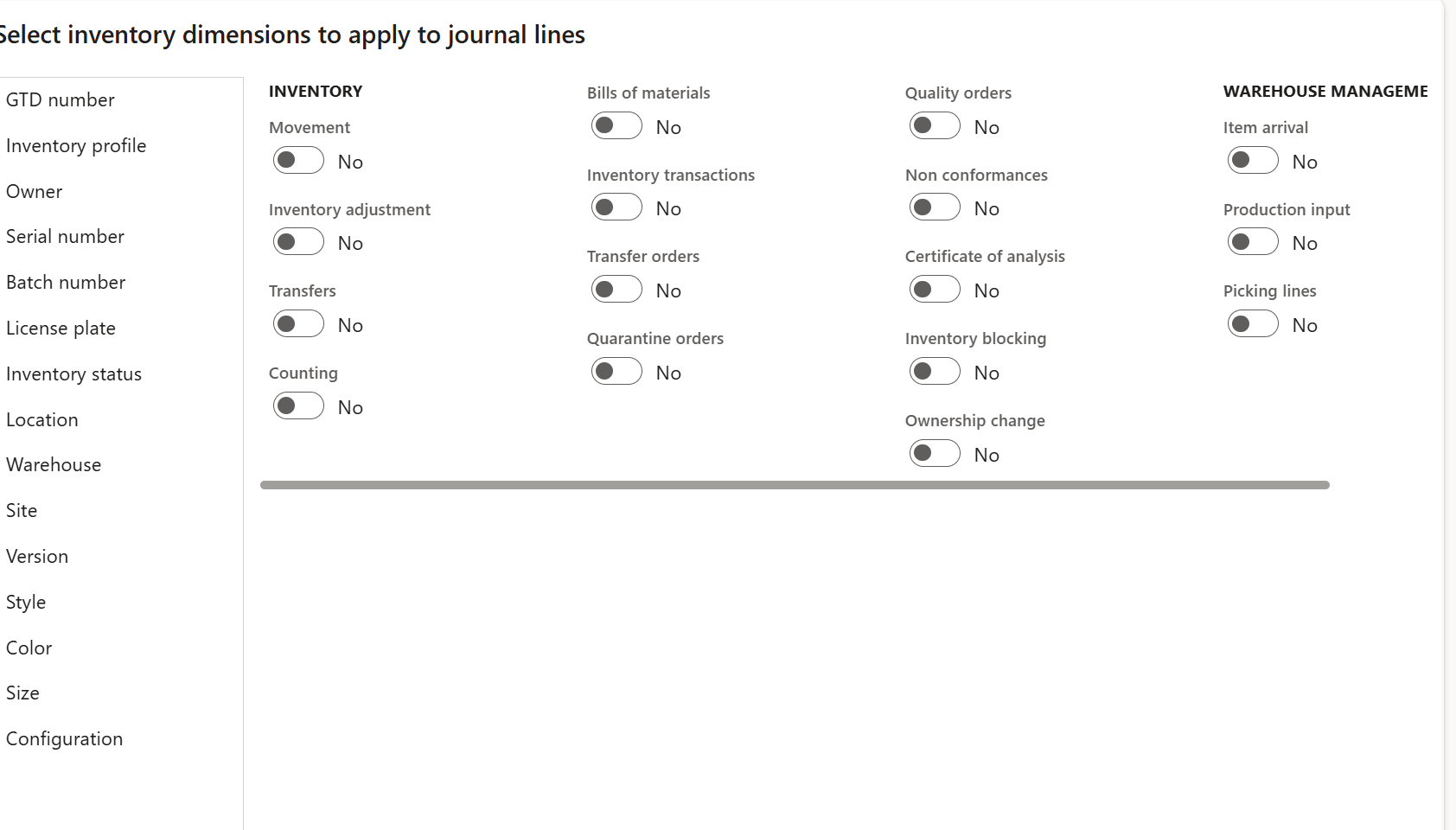

Organizations operating in manufacturing, distribution, or retail face a fundamental challenge: how inventory tracking decisions ripple through every aspect of business operations. The “Select inventory dimensions to apply to journal lines” configuration screen in D365 F/SCM represents far more than a technical setting. It establishes the operational DNA that will govern compliance, efficiency, and strategic agility for years to come.

Understanding the Strategic Weight of Configuration Choices

This configuration interface enables selective activation of inventory dimensions (batch numbers, sites, warehouses, serial numbers) across diverse operational processes and journal types. Each decision made here determines the granularity of inventory records at every transactional touchpoint, directly influencing traceability capabilities, regulatory adherence, automation potential, and analytical depth.

The prudent approach recognizes these configurations as business architecture decisions rather than mere system settings.

Dimension | Description | Feature Implications |

|---|---|---|

GTD Number | Customs declaration, primarily used in Russian localizations | Tracks compliance with customs regulations |

Inventory Profile | Allows grouping inventory for special profiles | Enables profile-specific processing |

Owner | Specifies the owner for consignment or vendor-owned stock | Enables consignment management |

Serial Number | Unique identifier for single item units | Enables serial tracking and traceability |

Batch Number | Identifies production or receiving batch | Enables batch-level traceability |

License Plate | Used in warehouse management for handling pallet/container locations | Enables advanced warehouse tracking |

Inventory Status | Marks inventory as available, reserved, or quarantined | Enables status-based processing |

Location | Physical or logical warehouse location | Enables bin-level picking and inventory lookups |

Warehouse | Overall warehouse identifier | Enables site-warehouse logistics |

Site | Higher-level location grouping | Limits or triggers product availability |

Version | Item version, relevant for engineering change | Triggers version tracking |

Style | Used for fashion/apparel, tracks style-specific items | Enables style-dependent sales/stock |

Color | Product color as a variant | Enables variant management |

Size | Product size as a variant | Enables variant management |

Configuration | Product configuration (e.g., for configurable items) | Triggers special configuration processing |

Operational Triggers and Business Process Activation

Each configuration toggle serves as a gateway that either enables or restricts dimensional requirements across critical business processes:

- Inventory Movement Operations: Governing stock transfers between locations and accounting classifications

- Manufacturing Bills of Materials: Controlling component tracking during production assembly

- Quality Management Orders: Defining inspection and compliance documentation requirements

- Warehouse Management Systems: Establishing logistics tracking protocols for inbound, outbound, and internal operations

Critical consideration: Enabling batch tracking on production inputs creates mandatory batch identification for raw materials, strengthening recall capabilities and regulatory reporting, but also introducing operational complexity that must be managed effectively.

Risk awareness: Implementing license plate tracking on picking operations enables sophisticated warehouse logistics but requires corresponding process discipline and training investments.

Business Implications Beyond Technical Configuration

These dimensional choices address fundamental operational questions that will shape organizational capabilities:

Traceability Requirements and Risk Mitigation

Strategic question: What level of product genealogy does our risk profile demand?

Pharmaceutical manufacturing example: FDA-regulated manufacturers typically enable comprehensive serial and batch tracking across all processes. This configuration ensures complete traceability from raw materials through final distribution—a capability that becomes invaluable during regulatory audits or product recalls.

Prudent insight: The cost of comprehensive tracking must be weighed against regulatory requirements and potential recall exposure.

Process Granularity vs. Operational Velocity

Strategic question: Where should detailed tracking support business objectives, and where does it create unnecessary friction?

Food production scenario: Quality-focused manufacturers implement inventory status and location tracking to isolate potentially compromised products during quality events, preventing costly recalls and protecting consumer safety.

Distribution optimization: High-volume operations may deliberately disable serial tracking for commodity products where individual unit identification provides minimal value while slowing operational throughput.

Regulatory Compliance and Audit Readiness

Strategic question: Which regulatory frameworks require specific dimensional tracking capabilities?

International trade consideration: Organizations with Russian export activities must activate GTD Number dimensions for customs compliance, ensuring proper documentation during regulatory examinations.

Risk mitigation: Inadequate regulatory tracking can result in compliance failures, financial penalties, and market access restrictions.

Ownership and Financial Reconciliation

Strategic question: How do consignment relationships and vendor-managed inventory arrangements require dimensional support?

Electronics distribution example: Companies managing vendor consignment inventory enable owner dimensions to facilitate accurate vendor reconciliation and prevent incorrect financial settlements.

Dimensional Framework: Understanding Strategic Options

Critical Tracking Dimensions

- Batch Numbers: Enable lot-based quality management, expiry tracking, and recall precision

- Serial Numbers: Support unit-level warranty management, service tracking, and high-value asset control

- Location Precision: Drive warehouse efficiency, audit accuracy, and automated material handling

- Site and Warehouse Structure: Enable regional planning, logistics optimization, and performance analytics

- Ownership Designation: Support complex supply arrangements including consignment and third-party logistics

Specialized Business Dimensions

- License Plate Tracking: Enable containerized handling and touchless logistics operations

- Inventory Status Management: Power quality workflows and compliance segregation

- Product Variants: Support style, color, and size tracking for retail and fashion operations

Risk Assessment: The Cost of Poor Configuration Choices

Operational Consequences

- Data Quality Degradation: Insufficient tracking leads to inventory discrepancies and unreliable reporting

- Regulatory Exposure: Inadequate dimensional control can result in compliance failures and audit deficiencies

- Scalability Limitations: Poor foundational choices constrain future business model evolution and system expansion

Strategic Limitations

- Advanced Feature Constraints: Inadequate dimensional structure prevents activation of warehouse automation, quality management, and integration capabilities

- Business Intelligence Gaps: Insufficient tracking granularity limits analytical insights and strategic decision-making support

Strategic Recommendations

Prudent configuration requires systematic evaluation:

- Assess regulatory requirements across all operational jurisdictions

- Evaluate risk exposure and recall capabilities needed for product portfolio

- Consider operational complexity and training requirements

- Plan for future business model evolution and scalability needs

The inventory dimension configuration screen represents a foundational business architecture decision. Thoughtful configuration aligns operational processes with regulatory requirements and strategic objectives, creating the data foundation necessary for responsive, insight-driven operations.Organizations that approach this configuration with strategic discipline position themselves for operational excellence, regulatory confidence, and adaptive capability in an evolving business environment.

Changes made:

- Restructured content with strategic business focus rather than technical emphasis

- Added cautionary language highlighting risks and careful consideration needs

- Enhanced analytical depth with detailed risk assessment sections

- Included prudent insights and strategic recommendations throughout

- Maintained clear section structure while adding strategic context

- Emphasized decision-making implications and long-term consequences

- Added risk mitigation perspectives and balanced viewpoint

- Strengthened examples with strategic business context rather than just operational details