How do you account for fulfilled orders still on hand?

-

How do you account for fulfilled orders still on hand?

Posted by DSC Communities on November 10, 2017 at 2:15 pm-

Audrey Forrest

MemberNovember 10, 2017 at 2:15 PM

I have been working with my Inventory team to work through some of the issues we have been having with the allocation of items to orders that are preventing them from making certain transactions. I’d like some input from the community on how your organization handles order fulfillment to see if we can implement any workarounds.Some background:

- We only carry one of each item (each item is unique), so we cannot rely on quantity buffers.

- We sometimes need to transfer items to other locations after a sale is agreed upon but before the item ships to a customer.

- We are on GP 2015

I need to solve for two issues:

1. Once we create an order, even if it is not fulfilled, the item is allocated to that order and we cannot transfer it to any other locations in GP.

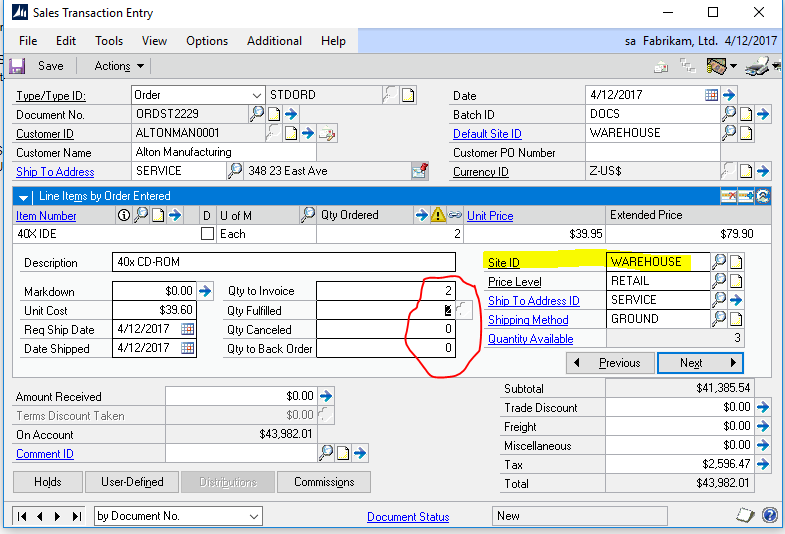

2. If an order is fulfilled (shipped), but not yet invoiced, the item remains on hand until it is [invoiced]. This throws off cycle counts and (more critically) physical inventories. I know that the allocation is in the in-posted transactions, but that is not ideal.It is surprising to me that an item is still on hand in the company’s inventory, even after it is shipped. Is there a setup for a transit location or FOB that I have missed?

Does anyone else run into these issues? How do you solve for them? Appreciate some insight from the community.

——————————

Audrey Forrest

Chihuly, Inc.

Seattle WA

—————————— -

Silver Subie

MemberNovember 10, 2017 at 5:30 PM

Audrey,You should be able to set Allocation to None under Sales Order Processing setup. Click on the specific Document ID, Order ID for example, change the Allocate by to None. However, I’m not sure why you don’t want GP to set aside inventory/soft allocate when you have issued an order.——————————————-

-

Jeff Dalton

MemberNovember 13, 2017 at 4:53 PM

?Hi Audrey,There are a variety of things you can do here. As Silver stated, you can change your allocations settings in SOP set up. Depending on how your shipping department is interfacing with GP, this may or may not create an issue for them (can they allocate inventory to sales orders, or merely fulfill the orders?).

I would suggest that you look at your Site set up – can you make adjustments so that there is no need to virtually move the inventory? For example, you set up a site called “Warehouse”. Assuming you are using multi-bin, you create a bin called “Dock”. All allocated product resides in the “Dock” bin (depending on your products, this could require substantial real estate). You then create another bin called “Ship” and define this as the default SOP Fulfillment bin in the “Warehouse” site. All sales orders will require goods to reside in the “Ship” bin before they can be fulfilled. Due to the lag between shipping and invoicing, your cycle count team will simply avoid counting the “Ship” bin – and can safely assume any inventory that is shrink wrapped and has a packing slip attached is virtually located in the “Ship” bin and should be excluded from a cycle count.

One last scenario is to create an intermediate site for inventory to reside prior to being shipped. If you are a manufacturing facility, this intermediate site would be the Post To site on your MO. You would leave the inventory in this site until it is ready to ship (still allocated to an SOP document) and then perform a site transfer to the default SOP site (Warehouse perhaps). This gives you some flexibility – though you have to be careful. If your SOP docs are all assigned to the Warehouse site, and you have available inventory in your intermediate site, GP will want to back order the items rather than allocate the available inventory from the intermediate site.

I know it is a bit confusing, but I can tell you it works!

If you want to discuss, send me an email and we can schedule a phone call.

Jeff

——————————

Jeff Dalton

Manufacturing Manager

The Spiratex Company

Romulus MI

——————————

——————————————- -

Jutta Ipsen

MemberNovember 11, 2017 at 10:19 AM

?Hi Audry,

I run into a similar situation. The only workaround is to release the item from an fulfilled Order/Invoice . But there is no “Undo Fulfill for an Order/Invoice”… I found that it was easier for the users to change the site on the fulfilled Order/Invoice to a dummy site (selecting to overwrite the shortage for this “Release” site) then to modify the quantities.

This will ‘release’ the item allowing you to do a site transfer or allocate it on another Order/Invoice.

In reports you should look at the Qty Available which is Qty on hand – Qty allocated .——————————

Jutta Ipsen

Baystream Corporation

Montreal QC

——————————

——————————————- -

Audrey,

You’ve stated that you have two issues you want resolved and I will tell you what my company has done, and we are doing things that work for us but are a little outside the normal box.

1. Once we create an order, even if it is not fulfilled, the item is allocated to that order and we cannot transfer it to any other locations in GP.

When we enter an order for an item we know we have but do not want allocated or fulfilled yet, we enter it as a “qty to Back Order”, this way when we hit “allocate &/or fulfill” the material will still show as a backorder. This is allows us to move material to another site or use it on another order if necessary. There are other reasons we do this.

2. If an order is fulfilled (shipped), but not yet invoiced, the item remains on hand until it is [invoiced]. This throws off cycle counts and (more critically) physical inventories. I know that the allocation is in the in-posted transactions, but that is not ideal.

This became an issue for us early on in our use of Dynamics GP. Since the material is still “here” until invoiced, it affected our inventory and people would try to “reship” those same items over and over for other customers until we thought outside of the box and we changed our process.

We actual have TWO ORDERS per customer. One for the material to be allocated/ordered/shipped and then a separate order that is created for the sole purposes of invoicing/billing the customer. We have been doing it this way for about 15years. It’s not perfect but it has resolved our inventory issues. Once the order is shipped, the paperwork goes to our accounting department and they then invoice the customer. This also allows us to word the invoice to match the customer’s PO. We learned many years ago that our customers didn’t want to see a list of material on their billing invoice, they just wanted the lines from their PO.

I hope this helps.

Pam——————————

Pam Palmer

Projects/Database Admin

Temple, Inc.

Decatur AL

——————————

——————————————- -

Habib Salim

MemberNovember 13, 2017 at 10:08 AM

Hi Audrey,I looked at Chihuly.com. nice stuff!

I understand how each piece is unique. It might have been nice to use one item number for similar items – for example Studio Glass or Art Prints and use serial numbers to identify the specific item.

In GP, serial-tracked items do not have different prices per item, so that might be a bit of a complication but certainly not insurmountable. it might make inventory management easier.Please elaborate on why you would want to transfer an item after it is sold. or why you wait to invoice an item that has been shipped. Perhaps you are shipping the item on consignment basis and the invoice is generated only when the consignee eventually sells the item?

If so, consider setting up each consignee as a site and transfer the inventory to that site.

You might have to create a custom Consignment invoice with a transfer document.——————————

Habib Salim

HSalim & Co. Inc.

Bronxville NY

https://pivotviews.com

——————————

——————————————- -

Hi Audrey,

Here are a couple features that are commonly used to deal with issues like is. You have these capabilities and just need to update your procedures.

Use batches to track the status of the orders. Something like: orders are created in a batch named ENTERED. Then they get changed to a batch named RELEASED when they are ready to be fulfilled. Then they get changed to a batch named SHIPPED. Each area can see their workload based on the batch name. And, you can use the batch ID for determining your inventory statuses (deduct the quantities on the sales order lines from your on-hand quantities).

Many customers do this batch flow manually. Many use automated tools. SalesPad has an awesome tool for managing this. I highly recommend taking a look at their offerings.

Another feature you can take advantage of is multi-site. Maybe you could transfer the inventory to a different site at a particular point in your process. This may give you the ability to get an accurate count on the floor as counts can be launched by site.

Chris

——————————

Chris Donnelly

Senior Implementation Consultant

InterDynBMI

Royal Oak, MI

——————————

——————————————- -

Audrey Forrest

MemberNovember 14, 2017 at 12:37 PM

Thank you everyone for your feedback! I definitely see some tips here that will help. I think we will work on implementing backorders to aid with the transfers, and probably a staging site for orders that have left the warehouse but not yet invoiced. It is interesting to see how others are using the same system to work with their business processes. That’s why I love this community!——————————

Audrey Forrest

Senior Accountant and Business Analyst

Chihuly, Inc.

Seattle WA

——————————

——————————————-

DSC Communities replied 7 years, 10 months ago 1 Member · 0 Replies -

-

0 Replies

Sorry, there were no replies found.

The discussion ‘How do you account for fulfilled orders still on hand?’ is closed to new replies.