Minimum and Inventory multiple in Master Planning

-

Minimum and Inventory multiple in Master Planning

Posted by DSC Communities on December 16, 2019 at 4:13 am-

Mohammad Gholami

MemberDecember 16, 2019 at 4:13 AM

Hi there,In the Master Planning algorithm, it seems that the ‘Inventory multiple’ (order multiples) has higher priority than Minimum amount in Item Coverage. Assume that Inventory multiple is 24 and Minimum is 15. The the reorder point becomes 24 instead of 15.

It is expected to place an order once the inventory level is below 15 but surprisingly the reorder point is now 24!I think it does not make sense since now the minimum amounts below the inventory multiple are not affecting the reorder point.

Does anyone have any suggestions?

#AX2012 #FinanceandOperations?? #admin #Functional #SupplyChain???

——————————

Mohammad Gholami

Ofogh Koorosh

—————————— -

Guy Terry

MemberDecember 16, 2019 at 4:59 AM

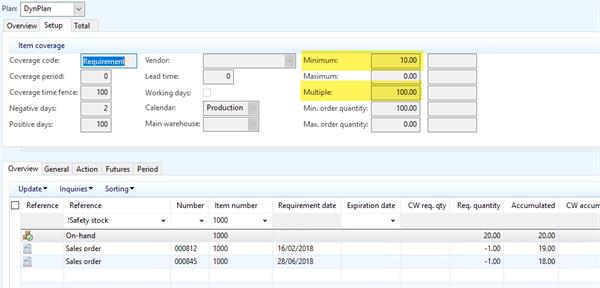

I do not believe this to be true…. AX will not try to raise a supply order unless it is predicting that On-hand will fall below the Item coverage Minimum, regardless of how your Order multiples are set. For example, the minimum on this item is 10. On-hand is 20, predicted to fall to 18. Order multipe is 100. AX is not proposing to purchase any more of the item, even though On-hand is below the Order multiple.——————————

Guy Terry

Application Consultant

Annata

Portsmouth

——————————

——————————————- -

Mohammad Gholami

MemberDecember 17, 2019 at 1:00 AM

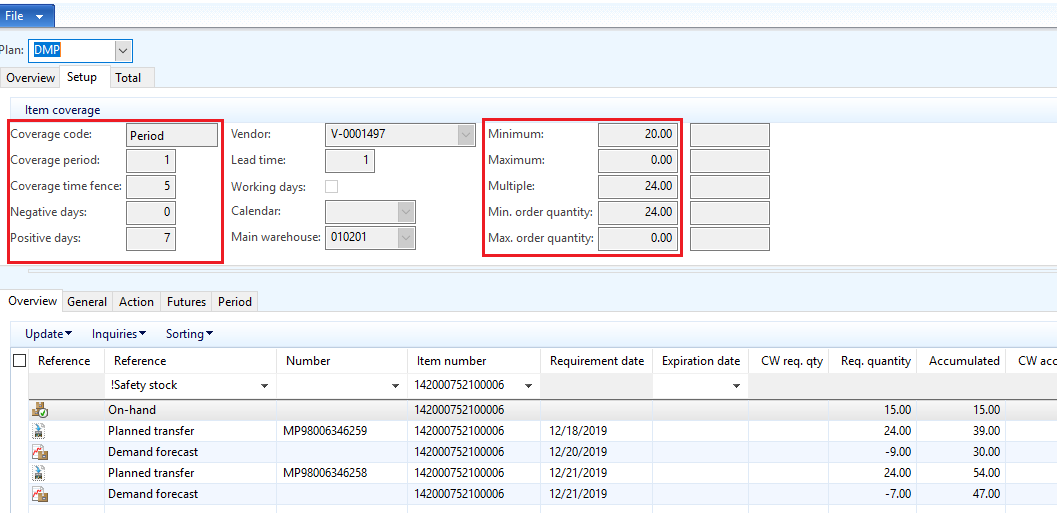

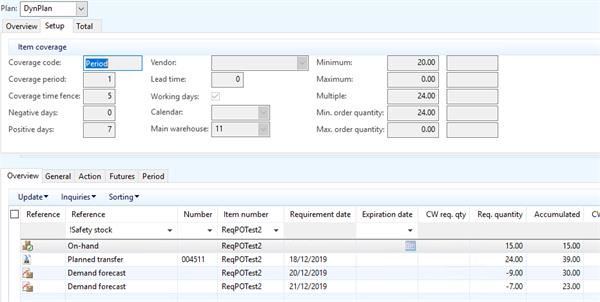

I totally agree with you but please take a look at the following screenshot.

The on-hand is 15 that is less than the minimum and correctly an order is placed to fulfill the minimum with 24 multiples.

The problem is that with the first planned order, we can cover the minimum and the following demand amounts and at the end of the coverage time fence the inventory level won’t fall below the minimum. So, Why another planned transfer is placed?

It seems that without the second transfer, at the end of the time fence, the inventory level (23) will not fall below the minimum (15) but it falls below the multiple (24).Regards,

——————————

Mohammad Gholami

Ofogh Koorosh

——————————

——————————————- -

Guy Terry

MemberDecember 17, 2019 at 3:43 AM

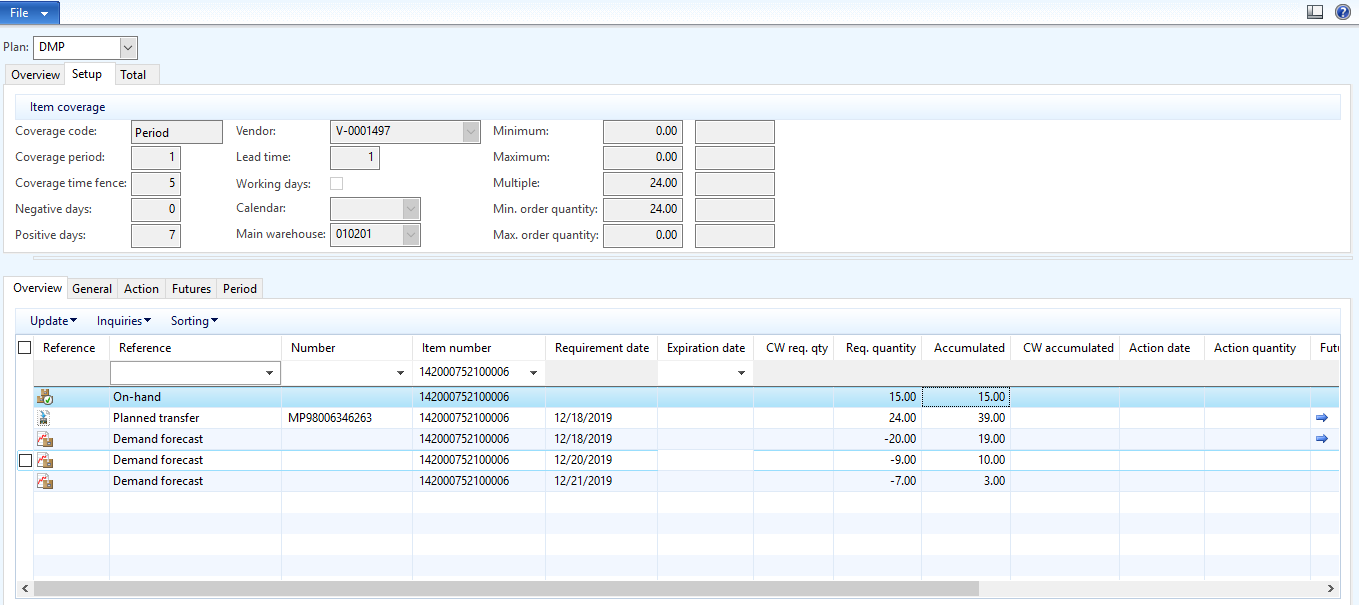

As on the other thread, I get the behaviour that you want in my R3 environment:

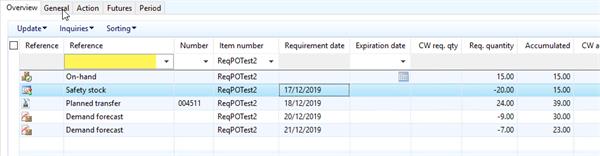

Something to try.On the Net requirements screen, remove the filter which is hiding the Safety stock transaction and make a note of the Requirement date:

——————————

Guy Terry

Application Consultant

Annata

Portsmouth

——————————

——————————————- -

I agree it should not be using the multiples. I question why your multiple is different than your minimum order quantity, typically multiple is some derivative of the minimum, for example minimum order is 10 multiple is 20 or in most cases it is set the same 10. then when ordering 11 it will suggest 10 or when ordering 16 it will suggest 20 since 16 is not a multiple. Look at your items minimum order quantity, the standard order quantity and the multiple , what are those values. and if you are using minmax coverage group, what are the values in your coverage group?

——————————

Paul Martin

Production Program Manager

Elite Comfort Solutions, LLC

Rutherfordton NC

——————————

——————————————- -

Mohammad Gholami

MemberDecember 17, 2019 at 9:19 AM

A agree with you. The point is that in our case the minimum and multiple order quantities are the same (As can be seen in the uploaded images). but the safety stock shouldn’t be necessarily derivative of multiples and that causes the problem.——————————

Mohammad Gholami

Ofogh Koorosh

——————————

——————————————- -

Mohammad Gholami

MemberDecember 17, 2019 at 9:16 AM

Thanks Guy, Your results are exactly what we are looking for. So, does it mean that the codes are different? and is it because of the Hot-fixes?I did your suggested change and the net requirement became as the following image.

I am looking forward to your kind suggestions.

——————————

Mohammad Gholami

Ofogh Koorosh

——————————

——————————————- -

Guy Terry

MemberDecember 17, 2019 at 9:40 AM

Because you get the behaviour that you want when you replace the Safety stock demand with some other type of demand, I would say that you should take the Hotfix that I talked about in the other thread (KB 4074644). It might not be that hard to install, since you are already on CU13.——————————

Guy Terry

Application Consultant

Annata

Portsmouth

——————————

——————————————- -

Mohammad Gholami

MemberDecember 18, 2019 at 3:57 AM

Thank you so much for your help. I will try it and let you know the results.——————————

Mohammad Gholami

Ofogh Koorosh

——————————

——————————————- -

George Zhao

MemberDecember 17, 2019 at 11:39 AM

You should note that minimum and multiple are about inventory transaction qty for the specific site/warehouse, not safe stock.

Master planning will not generate a order because on-hand qty fall below minimum.

The procurement, purchase or production, will be triggered by demand(s). Those can be sales, forecast, or safe stock.

Also if your default procurement site/warehouse is another and the minimum/multiple setting are different, you should see different result on planning run.

Unless you have another warehouse handling distribution, it may not be wise to set inventory minimum and multiple because it will limit the qty you can transact.——————————

George Zhao

PAR Technology

New Hartford NY

——————————

——————————————- -

remember that the minimum and multiple settings are just to default a suggested quantity, they can still be overridden. Basically they try to help you have some standards for things like a planned purchase where you get a price break on ordering 20 at a time. setting the minimum and multiple would suggest ordering 20 instead of 6 , but it is not a hard stop to prevent ordering, it just tries to assist in helping maintain cost and inventory

——————————

Paul Martin

Production Program Manager

Elite Comfort Solutions, LLC

Rutherfordton NC

——————————

——————————————- -

George Zhao

MemberDecember 18, 2019 at 1:24 PM

Master planning will follow the minimum and multiple settings. DIXF will block import with qty NOT meet the minimum/multiple setting. Manual entries will get a warning but it can be processed if minimum/multiple not meet.——————————

George Zhao

PAR Technology

New Hartford NY

——————————

——————————————-

DSC Communities replied 5 years, 10 months ago 1 Member · 0 Replies -

-

0 Replies

Sorry, there were no replies found.

The discussion ‘Minimum and Inventory multiple in Master Planning’ is closed to new replies.