Error on Cost Calculation

-

Error on Cost Calculation

Posted by DSC Communities on June 26, 2019 at 1:40 pm-

Robin Finnell

MemberJune 26, 2019 at 1:40 PM

How do you mass calculate the cost on products when they have the same co-product?Scenario:

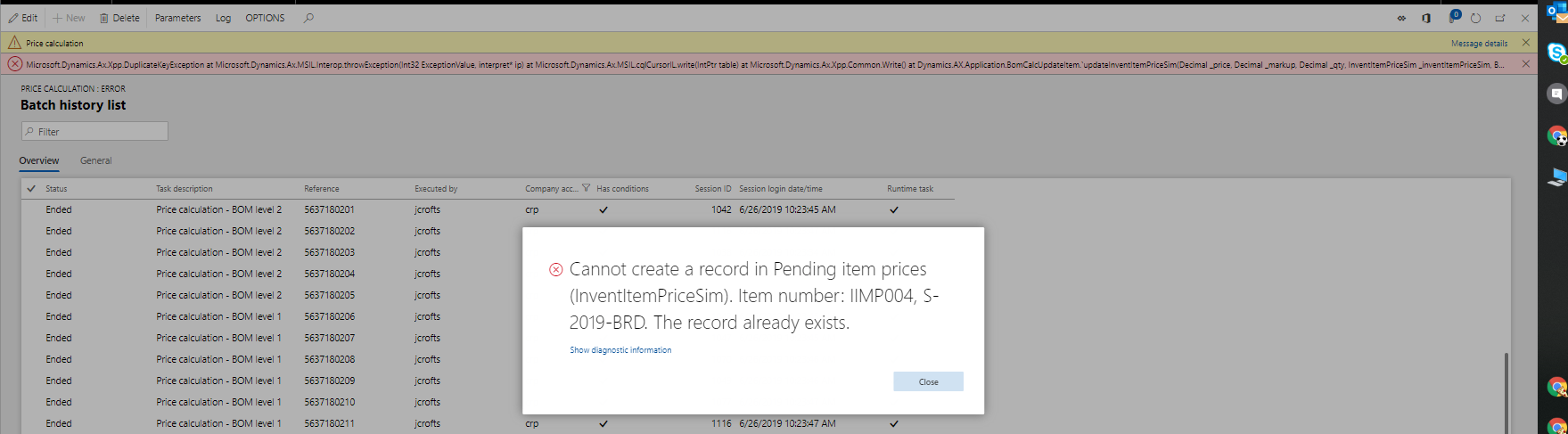

We produce multiple items with the same co-product. For instance, we create two different types of cheese, each with the same output of whey cream. Currently, we cannot calculate the cost of all items because it throws the following error:

I am certain that there are others who face the same scenario. What have you done to alleviate this issue?Thanks in advance!

——————————

Robin Finnell

Continuous Improvement Coordinator

Operations Lead – D365FO/MES Implementation

Tillamook County Creamery Association

Tillamook

—————————— -

Robin,

Generally, in a cost roll process, you’d want to start by calculating and activating new costs for your subassembly items and build your way up.

——————————

Ian Gorman, PMP, MCSE

Consultant

——————————

——————————————- -

MICHAEL MILLS

MemberJune 27, 2019 at 8:12 AM

I agree with cost rolls need to start with components, then subassemblies, and finally finished goods. There might be a second issue and that has to do with the type of co-product vs. by-products for the whey cream. If I was trouble shooting I would take a look at the different cost impacts based on the selection of co vs. by-products. If you search on “About co-products and by-products” the article will provided insight. My suggesting is to create a flat formula for the product that produces whey (no subassemblies in formula), rollup the components in the formula and make active, then try to roll-up finish goods cost (test 1). In test 2 change the whey product line from co to by-product and try your cost roll at the finish good level again. I am interested in the results of your testing if you want to share the results.——————————

Michael Mills

AX D365 Enterprise Consultant Operations

Blue Horseshoe Solutions

Carmel, IN

——————————

——————————————- -

MICHAEL MILLS

MemberJune 27, 2019 at 8:17 AM

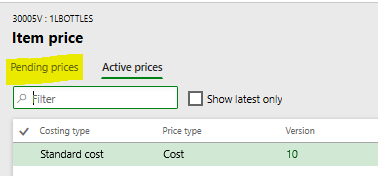

One last thought, after looking at the error message one more time. I looks like you might have a pending cost that has not been made active.

Navigate to Release items > Manage cost > Item Price and check pending price tab. If there is a pending price delete it.——————————

Michael Mills

AX D365 Enterprise Consultant Operations

Blue Horseshoe Solutions

Carmel, IN

——————————

——————————————- -

Michael,

You bring up a great point.

Robin,

You may want to delete all pending costs that are currently associated to your costing version prior to running the calculation process.

——————————

Ian Gorman, PMP, MCSE

Consultant

——————————

——————————————- -

Joe Crofts

MemberMay 19, 2021 at 6:36 PM

Hey everyone I am picking this back up. The comments are helpful, but not quite what we were looking at.I have done some more research and we have been given several answers. Let me demonstrate the issue a little clearer.

Say we have 3 items

A

B

CThese items all have a coproduct D that is created. Same coproduct comes off all processes

So each time I try and calculate the cost for A, B, and C at the same time the cost roll process try’s and attempts to create a new pending item price for coproduct D.

The process is not designed to have a 1 single coproduct on multiple formula Versions.

We are wondering if this has been run into before and if anyone has come up with a solution on how to deal with this.

Thanks,

Joe

——————————

Joe Crofts

Finance Project Manager

Tillamook County Creamery Association

Tillamook OR

——————————

——————————————- -

I’ve worked through the same problem at a client, and found no easy solution that was easy to manage. The best solution we came up with was:

- Create a fake item to be the parent of the formula that costed the shared co-products

- Set up the formula with a single component that has a zero cost

- Set up the route with a single operation that has a zero cost

- Set up the shared co-products as co-products in the formula for the fake item. It does not really matter what the cost allocation percentage is, because there is no cost from the formula to allocate anyway.

- Make sure that the cost allocation percentage on the shared co-products in all the other formulas is zero, so they get no cost from the formulas you will actually be using.

- Set up a burden factor that applies a rate to an item.

- Set the calculation for all items to have a rate of 0

- Set the calculation each of the shared co-products to be the standard cost you want the co-product to have.

- When you run the calculation, the shared co-products will get the cost you want applied to them.

I’m not claiming this will be the ultimate solution for you, but it worked well enough for several reasons:

- The cost of the shared co-products was a somewhat arbitrary cost rather than a value to be calculated with some degree of precision

- It was easy to find the calculation that assigned cost to the shared co-products when you wanted to change that cost

- You could update the cost of the shared co-products by running the cost calculation on the fake item, without affecting the costs of any other items.

- The co-products had costs in the BomCalcTrans table, which meant they are handled better in production order variance calculations

I think the ideal solution would be to add a field to the released products table to allow us to specify the formula that will be used to calculate the cost of a co-product. There is a suggestion in the Microsoft enhancements list to do that, but I doubt whether it has accumulated enough votes to get on anyone’s radar.

——————————

Kevin McLean

Strategic Solutions NW

Beaverton OR

——————————

——————————————- - Create a fake item to be the parent of the formula that costed the shared co-products

DSC Communities replied 6 years, 2 months ago 1 Member · 0 Replies -

-

0 Replies

Sorry, there were no replies found.

The discussion ‘Error on Cost Calculation’ is closed to new replies.