Best Practices for Item Planning Parameters

-

Best Practices for Item Planning Parameters

Posted by DSC Communities on December 19, 2017 at 10:43 am-

Kristina Frank

MemberDecember 19, 2017 at 10:43 AM

Good Morning!We use NAV 2015 and are taking steps to utilize the requisition worksheet. Does anyone have best practice suggestions for setting up the planning parameters for items?

Is there a report in NAV that provides sales history/trends to help us determine our reorder-point parameters?

How often are you reviewing your parameters and updating to prevent overstock and potential obsolete inventory?

Thank you in advance for any advice provided.

——————————

Kristina Frank

Controller

Cline Tool & Services

Newton IA

—————————— -

Here is a starting point right from Microsoft:

Setup Best Practices: Planning Parameters

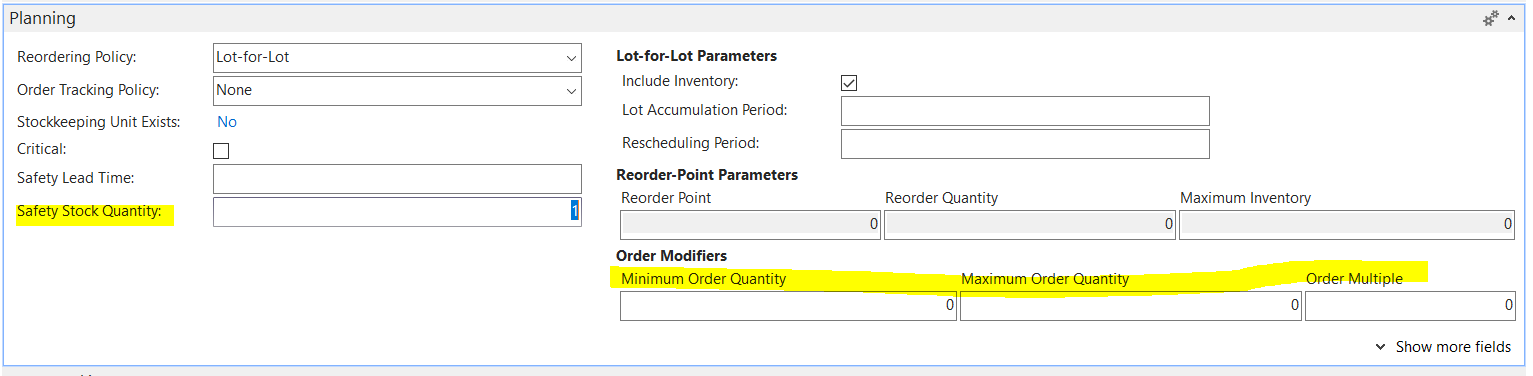

The Planning FastTab on the item card is the center of a company’s supply chain. Setting the correct planning parameters is very important for cost-effective inventory control and high customer service.

The following table provides best practices on how to set up selected planning parameter fields. For more information about a field, choose the link in the Setup field column.

Setup field Best practice Comment For more information, see Setup Best Practices: Reordering Policies.

Select Never when the item is planned using a reorder point.

In manufacturing, select Never to allow the planning system to cover all demands.

Select Optional for items that you may want to reserve for top-priority customers.

Select Always for non-unique items, such as items of type miscellaneous that are inbound for specific demands.

Reservations generally counteract the purpose of planning, which is to balance demand and supply. Therefore, items that are set up for planning should generally not be reserved.

If the user reserves an inventory quantity for future demand, then the planning foundation will be disturbed, and the reorder point may not work correctly. Even if the projected inventory level is acceptable with regard to the reorder point, the quantities may not be available because of the reservation.

Set with regard to the supplier’s flexibility.

If the supplier accepts last-minute changes to orders, then use a longer period. If the supplier requires firm planning, then shorten your period as much as possible.

For information about the global setup, see Default Dampener Period.

For information about the global setup, see Default Dampener Quantity.

Always select when you are using the Lot-for-Lot reordering policy.

Do not select only in special situations, such as when inventory items are not sellable.

Set between 1D and 6D.

Set a safety lead time of at least one day to make sure that supplies are available on the day before they are needed.

If using a new supplier, define a longer time until their delivery performance is known.

In manufacturing, define longer safety lead times for critical components.

Supply that is planned by the system to avoid a stock-out will arrive on the same day that the stock-out occurs. This may be several hours too late if, for example, the demand is needed in the morning and the supply arrives in the afternoon.

Use for items with large demand fluctuations.

In manufacturing, use for critical components.

Use for items that are subject to service agreements.

If the Reorder Point field is not filled, then the safety stock quantity also functions as a reorder point.

If you want only few big orders and you accept to carry inventory, then set a long lot accumulation period.

If you want multiple small orders and minimal inventory, then set a short lot accumulation period.

The lot accumulation period is generally the longest period that you will carry inventory.

Base the reorder point on the item’s demand profile.

If historical data shows that the item’s average demand is 100 units during a lead time of seven days, then the reorder point can be set to 100 as a minimum.

This means that when the inventory level falls below 100 units, then the planning system will suggest to replenish because it takes seven days to supply the item, and there must be enough to cover the demand within those seven days.

Leave blank, meaning that the inventory level is checked every day.

Checking the inventory level every day ensures optimal reorder point planning.

In expensive manufacturing, set to 0.00001.

Large rounding quantities of scrap or material consumption can amount to very large inventory costs. It may therefore be relevant to set the smallest rounding precision to minimize this potential cost.

——————————

Holly Kutil ~ NAVUG All-Star

American Ring/Business Intelligence Dir.

Solon, OH 44139

**Great Lakes Chapter**

?? Women In Dynamics ??

——————————

——————————————- -

Jason Nicolaou

MemberDecember 20, 2017 at 8:38 AM

?Kristina this is certainly an interesting topic. May I ask why you are using the Requisition Worksheet versus the Planning Worksheet? Second, what sort of problems do you have with inventory management today? Finally, what are your goals for inventory (increased fill rates, decrease total inventory on hand, minimize spoilage, etc.)? Yes i realize that they all are important, but I am asking what is most important to this initiative?Happy Holidays!

——————————

Jason Nicolaou

Solutions Architect

Socius

Dublin OH

——————————

——————————————- -

Kristina Frank

MemberDecember 21, 2017 at 4:41 PM

You ask some good questions … Our company is expanding and adding new customers with requirements different than our current customer base. We are trying to become efficient with our inventory ordering and trying to set up processes that flow from customer to customer and vendor to vendor. Our current process is very customer/vendor specific which makes it hard for a new employee to learn and understand our processes.We are looking at the requisition worksheet because the product we are managing at this point is product we are distributing, no manufacturing involved. We are buying the product and reselling it so we felt the requisition worksheet would meet our needs. I am interested to hear if there is a feature of the planning worksheet that will work differently than the requisition worksheet and make if fit our needs better.

We have a variety of inventory management practices we would like to improve. 1. We want to order product before we run out and a customer needs it. 2. We would like to reduce the number of orders sent to the same supplier in a day/week. For example, can we combine an order to save shipping costs or meet minimum order levels. And the list continues.

Our main goals with inventory are to prevent buying to much inventory which could end up becoming obsolete and making sure we have enough inventory on hand to meet our customer’s needs so we do not stop their production.??

Thank you for the feedback!

——————————

Kristina Frank

Controller

Cline Tool & Services

Newton IA

——————————

——————————————- -

The planning worksheet will manage production, assemblies, purchases and transfers at the same time or you can filter to do each individually.

The requisition worksheet does not handle production or assemblies.

Use lot for lot to help minimize ordering frequency. Use 7D to combine all orders for the week. Set your order minimums and multiples to an appropriate size to avoid ordering broken cases.

If I remember correctly, there is an inventory aging report. We did a report that lets a user evaluate inventory by age, margin and velocity and display the results graphically to monitor according to user defined parameters, so, I’m foggy on the native NAV report.

——————————

Ron Ketterling

President

Business Automation Specialists of MN, Inc.

Minneapolis MN

——————————

——————————————- -

Marguerite Manelski

MemberDecember 22, 2017 at 7:51 AM

I agree with Ron as lot for lot seems to be the key to a lot of this. We tried the different settings and found that on an item we did not want to “over” stock we would use lot for lot with the minimum qty filled in so that we knew what to buy.If you find that you have a customer that is consistent with their usage you may want to consider using fixed reorder which would prompt for a buy when your stock is below a certain level.

It’s also important to remember that these are suggestions based on your settings so you can adjust if you find that your original setting is accomplishing what you want.

You may also want to think about how often a vendor ships to determine how often you should review them. If you have a vendor that ships weekly you’ll probably want to review weekly, if that vendor only ships once a month you may want to review bi-weekly.

——————————

Marguerite Manelski

Purchasing Agent

American Ring

Solon, OH

**Great Lakes Chapter Member**

——————————

——————————————- -

The biggest point of concern on “Lot for Lot” policies, is how fast you need to be able to deliver the product. If all of your orders are for future dates, then Lot for Lot is a great policy. However, if customers place the order and expect you to ship it same day, Lot for Lot will eventually stock out.

Fixed Reorder/Max Quantity Policies are for stock products. You sell out of stock and replenish based on when your stock hits a specific level. It doesn’t matter if the orders are for today or future orders, as the system plans based on the date you fall below your reorder point (even if that is in the future). It is important to monitor your Reorder Point to ensure it is high enough to cover all demand while the re-supply is in route.

Lot-for-Lot/Order are lean inventory policies. The goal is to stock as little as possible. These policies work for future demand environments. Even if you use Min. Order Qty (or Order Multiplier), the system can still zero out, with no planned supply. This can be painful in a quick ship environment.

Proper parameters depend on your business model and your past sales, making the huge assumption they are an accurate indicator of future sales.

——————————

Ben Baxter

Consultant

Accent Software, Inc.

Carmel IN

——————————

——————————————- -

Jason Nicolaou

MemberJanuary 2, 2018 at 9:34 AM

good points about the reordering policies. There is also something to be said about good old experimentation with a sample set of products to see what happens. The Safety Stock Quantity and Order Modifiers can be manipulated to offset some of the challenges that have been identified with Lot-for-Lot.

In many cases the policy of “order” is used for custom products that are not stocked at all, but are an inventory item. I do agree that the other policies target products that will be stocked for the foreseeable future. One final point is that the reordering policy can be changed as the life cycle for the item progresses. As the “Edit in Excel” function is added in more places for newer versions updating will become even more efficient. An example would be to filter your search by a whole item category code or product group code, say parachute pants, edit in excel to change the policy to “order”, and then re-run the requisition worksheet accordingly. Best of luck and please keep posting your progress because this is a VERY interesting topic. ?——————————

Jason Nicolaou

Solutions Architect

Velosio

Dublin OH

——————————

——————————————- -

Carey Leung

MemberDecember 23, 2017 at 6:14 PM

You can use Stock Keeping Units to enter parameters for different item/variant/location combinations. If using SKUs, consider whether you want to enter parameters on the item card as it will be added to requirements specified in any SKUs for the item.——————————

Carey Leung

Catapult ERP

Vancouver

——————————

——————————————-

DSC Communities replied 7 years, 8 months ago 1 Member · 0 Replies -

-

0 Replies

Sorry, there were no replies found.

The discussion ‘Best Practices for Item Planning Parameters’ is closed to new replies.