Assembly dates

-

Assembly dates

Posted by DSC Communities on September 5, 2017 at 1:11 pm-

Marguerite Manelski

MemberSeptember 5, 2017 at 1:11 PM

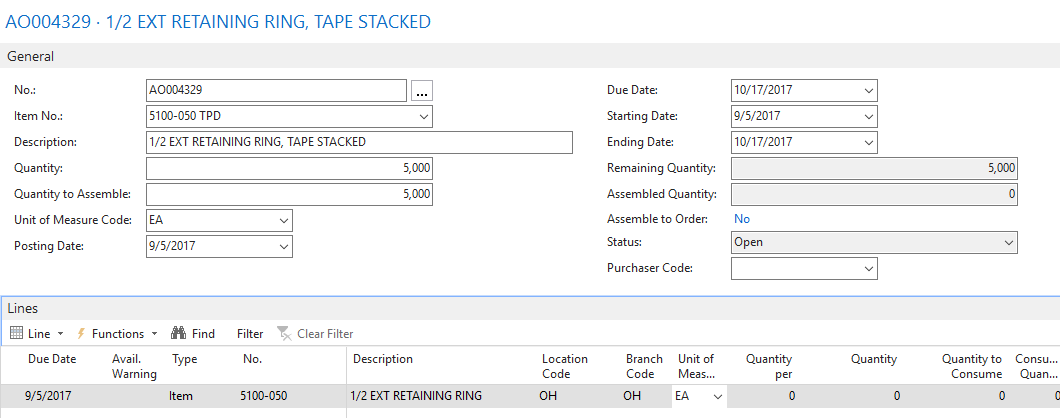

I am looking for some help with the dates on assembly orders. I want the start date to represent the date that the assembly order was created and the due date to represent when the assembly order needs to be completed. I am noticing that when I enter a start date in the header the due date on the line will represent the same date.

I am not sure why this would be happening as this makes no sense to me. I would think that the Due date in the header & the line should be the same. Not sure if we implemented a mod that is messing this up.Has anyone else ran into this issue? If so how did you fix it? If not any suggestions would be greatly appreciated.

——————————

Marguerite Manelski

Purchasing Agent

American Ring

Solon, OH

**Great Lakes Chapter Member**

—————————— -

Ian Ray

MemberSeptember 5, 2017 at 1:52 PM

I may be misunderstanding, but I think the starting date is the date that the assembly order needs to be started in order to satisfy the lead time and ending date. The due date on the lines are when the items must be available for the assembly order. Thus, if you start on day X, the items must be available on that day.The documentation is a bit confusing to me… it says the due date on the line is copied from the header due date and can be changed. But, it wouldn’t make sense to me to have the item due when the order is if there is a lead time.

——————————

Ian Ray

Cypress Grove

Arcata CA

——————————

——————————————- -

Marguerite Manelski

MemberSeptember 5, 2017 at 2:32 PM

Is there a way to have the date we entered the assembly populate, maybe a mod, so we will have record of when it was entered?We use assemblies for several different things and need to have record of when it was entered, when we stated it would be complete & if there is a push out for that. Just as there is the promised & requested dates on PO’s we would need to use assemblies in a similar way.

Example is we need to send parts out for a secondary process. We enter the AO but parts will not be in our building for 3-4 weeks. Once they return we will then do a third process, that could take another 2 weeks, to make the item “complete”. So would I make the start date the date parts will be done with the second process and ready to start the third process? If so the ending date and due date would be the date that parts would be completed. If something changes we would leave the ending date as the original date & the due date in the header would now be the push out date?

Sorry, we have had issues with the way we use dates and want to make sure I have the correct understanding.

——————————

Marguerite Manelski

Purchasing Agent

American Ring

Solon, OH

**Great Lakes Chapter Member**

——————————

——————————————- -

There are three dates on the assembly order, Start Date, End Date, and Due Date. My understanding is as follows:

The Due Date is usually the work date if you enter the assembly order manually. If entered from a sales order, it should be the shipment date of the sales order.

The Ending Date starts from the Due Date and works backward based on the safety lead item (from the item card) and the warehouse handling time (inventory setup). Usualy this is one day since NAV likes to have orders done one day prior to shipment.

The Starting Date works off the Ending Date and is the lead time specified on the SKU (1st) or the item card (2nd).

The one thing it doesn’t take into account is the lead time for getting component parts in. You can manually change the dates after the order is entered but NAV will ask whether to change the other dates accordingly. If you don’tm want them to change you would need to answer “no” of customize the code.

——————————

Dave Wiser

Controller

Beckwith & Kuffel

Seattle WA

——————————

——————————————- -

Have you considered Production Orders? You have more flexibility and the Routings will take care of your lead times and also generate a Purchas Order for the outside process and apply the cost to the finished product.

——————————

Ron Ketterling

President

Business Automation Specialists of MN, Inc.

Minneapolis MN

——————————

——————————————- -

Amanda Mayer

MemberSeptember 6, 2017 at 9:41 AM

Ron has asked exactly the same question that I was going to ask. Especially since you send out for secondary processing, the subcontractor functionality is pretty slick and provides more structure to the overall process.——————————

Amanda Mayer

New View Strategies

Milwaukee WI

——————————

——————————————- -

Well…..not going to answer that as I do not want to point the finger at anyone 🙂 but we were gently pushed away from that thought over to assemblies along the way…..

Would love to hear more about the production orders though, you have got my attention! 🙂

——————————

Holly Kutil

American Ring/NAV Admin

Solon, OH 44139

**Great Lakes Chapter**

?? Women In Dynamics ??

——————————

——————————————- -

Assembly orders are one leg of normal manufacturing. They do allow labor posting with resources. Production Orders also have a bill of material, but also have a routing. The BOM is like the list of ingredients in a cake, while the routing is the instructions on how to make the cake.

The instructions include the steps (operations) and the tools (machine or work centers). Additionally, there can be work instructions, quality steps, tools and outside processes.

Outside processes are especially important in today’s manufacturing world because so many companies are involved in making one item. Subcontracts can include the costs of these processes and also create the purchase order for the work performed. Thw costs or the service are included when the purchase order is received. One draw back, if you need cradle to grave tracking is that the the item you send out has already been consumed or not yet produced so there is no record of the item leaving your premises. You can fix this by having multi-level BOMs and routes. We had to resolve this issue for our Easy Bound Book product for the firearms industry in another way.

Perhaps we can touch base at Summit of you would like more insight.

——————————

Ron Ketterling

President

Business Automation Specialists of MN, Inc.

Minneapolis MN

——————————

——————————————-

DSC Communities replied 7 years, 12 months ago 1 Member · 0 Replies -

-

0 Replies

Sorry, there were no replies found.

The discussion ‘Assembly dates’ is closed to new replies.