Add parts and labor to a finished goods part

-

Add parts and labor to a finished goods part

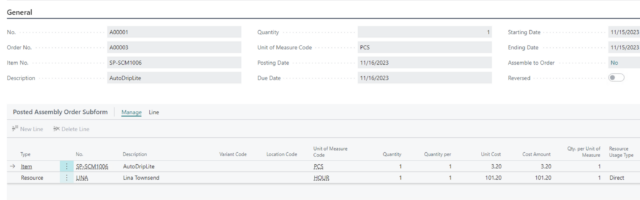

Hi all: I’m trying to figure out the best way to add parts and labor to a finished goods part. Physically, we are pulling the FG part out of inventory, adding a couple parts to it and associated labor to do so, and putting it back in inventory. We want to keep the same part number throughout – it’s just an improvement. It seems to me that I should be able to use a Production Order to pull the current FG part out of inventory, add the two parts and the labor, then complete it back to the same part, but since there is already a BOM and routing for the FG part that includes all the parts that originally went into completing the FG part, I’m not sure how to do this. Any thoughts?

The discussion ‘Add parts and labor to a finished goods part’ is closed to new replies.